Pharmaceutical Packaging

Just like pharmaceutical companies, end user also demand safe and high-quality packaging for the medication they take. That’s why at Uniworth, the wide range of packaging films offered that includes rigid PVC Blister Film , PVC/PVdC films, Alu Alu laminates, and Triplex films to pack the pharmaceutical products in the best possible way, which protect the products against environmental conditions and microbial contamination, and reduce the waste.

The company is the global supplier of the high-quality pharmaceutical packaging films that are manufactured and distributed under safe environments and industry-standard compliances.

- High degree of barrier to oxygen, gases, and moisture

- Available in varied thickness and coating level

- Withstand under extreme temperature and pressure

- Completely non-toxic, tasteless and aroma less

Rigid PVC Film(Blister Packaging)

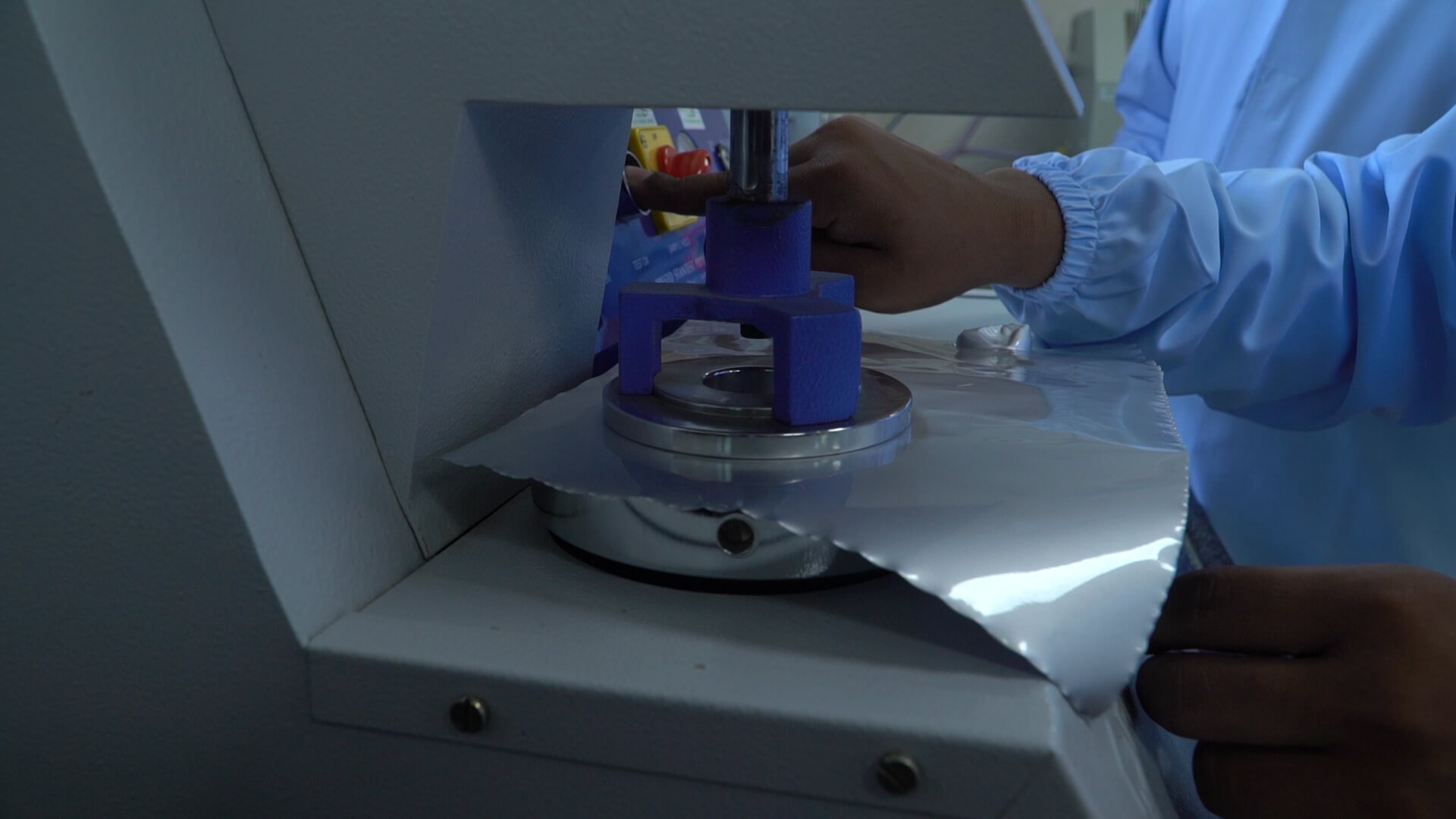

Sound health is always packed in non-toxic and chemical-free foods and pharmaceutical drugs. For the best packaging, Uniworth manufactures the excellent rigid PVC film leveraging pharma-grade raw materials and latest calendaring process. The films are manufactured under controlled environment as per current GMP norms and comply with all the food and pharma packaging regulations.

The modern packaging solution by Uniworth ranges from 50 to 700 microns and require less fuel in manufacturing and transport as opposed to metal, glass or other materials. That’s increasing its usage and demand in the packaging across the world.

USFDA Type III DMF NO. 032495

PVC / PVdC

In tropical regions, the hygroscopic sensitive products packaging need to be of high quality. PVdC coated PVC films manufactured by Uniworth are considered as best for the blister packaging due to the coating over rigid PVC films. The PVdC coating of optimum thickness on one side of the packaging minimizes the gas and moisture permeability.

The thickness of PVC ranges from 200 to 350 microns with coating GSM 20, 40, 60,90 and 120 GSM to suit the different pharma and food packaging requirements. Also, PVdC coated PVC film is produced as per current GMP norms and in compliance with pharmaceutical packaging regulations.

USFDA Type III DMF NO. 032496

Alu-Alu Laminates ( Cold Forming Blister )

The unmatched quality of Alu Alu laminates was developed and manufactured at Uniworth to provide the best barrier protection to the pharmaceutical packaging from oxygen ingress, moisture ingress, aroma, and lights. The cold forming blister is produced under clean and hygienic conditions and processed in the controlled environment in compliance with GMP requirements that ensures top-grade quality, fracture-free cavity and de-lamination resistance for the longer run.

The use of Aluminum as a core material and being an inert and most barrier material ever defined is the main advantage of the cold forming blister because of the high resistance to water and oxygen.

USFDA Type III DMF NO. 032494

The precautions to be taken to better handle the blister

- The materials are packed by stretch wrap followed by corrugated boxes

- The material to be kept at ambient room temperature

- Direct sunlight should be avoided

Triplex – PVC /PE/PVdC

Some sensitive or hygroscopic pharmaceutical products need a high level of protection against moisture and oxygen where conventional PVC or PVdC films won’t work. That’s where triplex (PVC/PE/PVdC), the best blister film for medicines packaging is more favourable.

Uniworth’s triplex film is manufactured by laminating PVC film with PE layer followed by PVdC coating on it, where all the operations like- calendering, lamination and coating are done under one roof in a controlled environment and in an accordance to national and international standards.

USFDA Type III DMF NO. 032497

Food Packaging

As the modern trends and preferences are replacing the old, the innovative and qualitative packaging of the food grade has become all-imperative. At Uniworth, the food grade packaging materials and PVC films are manufactured on the excellent calendar lines along with special care and under the controlled environment. Also, the products are the best fit for different food packaging films requirements as they can be easily tailored to the clients’ needs of diverse width, grades, and shades.

- Hygienic, non-toxic, and odorless in nature

- Available in different sizes, grades, and colors

- Stable in extreme temperature, moisture, and pressure conditions

- Glass-like clarity and high gloss

- Excellent resistance to stress and cold cracking

- Comply with latest USP for toxicity and heavy metal content

Stationery Packaging

Uniworth is a leading manufacturer and supplier of the wide range of the industry products.The stationery grade PVC-based films such as PVC – Play card grade, PVC – Cooling tower fill grade, PVC sheet, and Matt PVC of great quality are produced that are moisture-proof, lightweight and stable in nature. Besides, the products are built in a clean and safe environment.

- The films are available in the range of colors as required

- The sheets are created in lay-flat format

- Have the brilliant die cutting properties

- Excellent anti scratch property